3D Printing: How It's Changing the World as We Know It

5 min read

05 Aug 2024

3D printing, also known as additive manufacturing, is revolutionizing various industries by enabling the creation of complex objects layer by layer from digital designs. This article explores the transformative impact of 3D printing, its applications across different sectors, and its potential to reshape manufacturing and innovation.

Understanding 3D Printing

Layered Manufacturing: Building objects by depositing materials layer by layer, guided by digital blueprints or CAD models.

Material Options: Utilizing a wide range of materials, including plastics, metals, ceramics, and composites, to achieve diverse functionalities and properties.

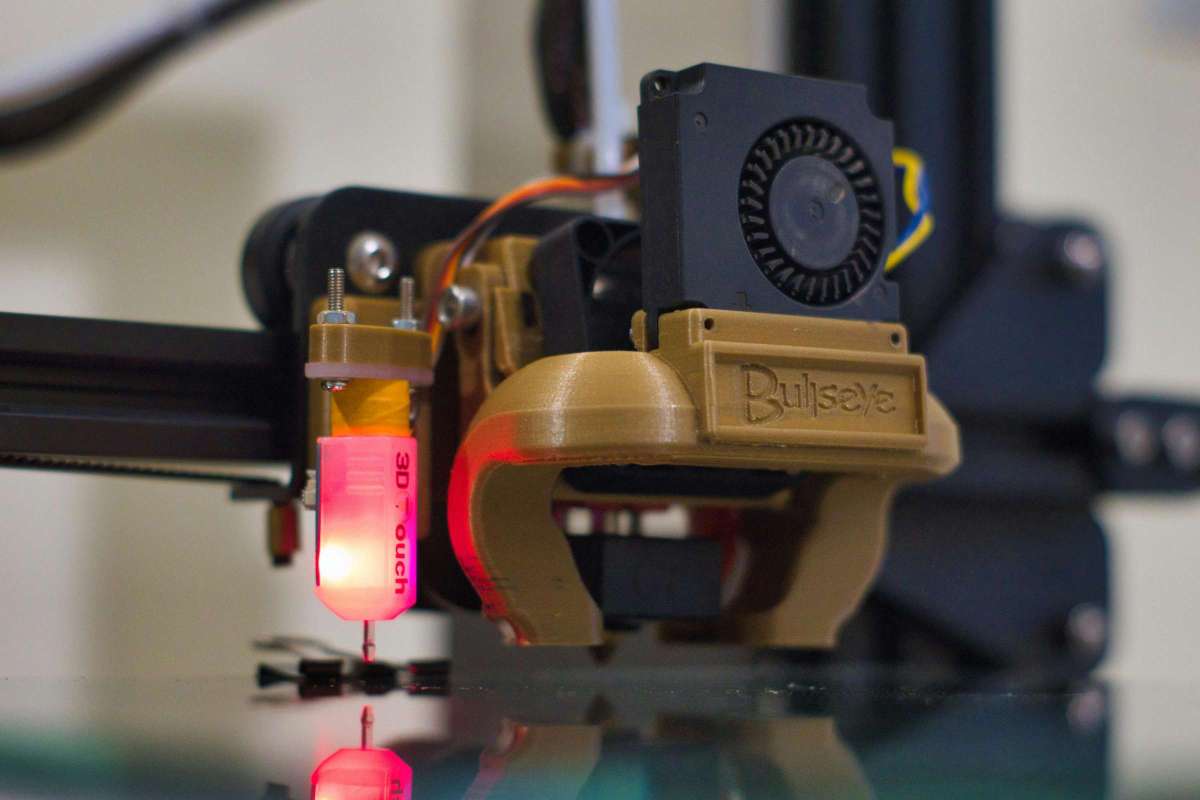

Printing Processes: Employing techniques such as fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), and binder jetting to create precise, customized parts.

Post-Processing: Finishing printed objects through processes like curing, polishing, or painting to meet specific requirements.

Applications Across Industries

Healthcare: Producing personalized medical devices, prosthetics, and implants tailored to individual patient needs.

Automotive: Rapid prototyping of vehicle parts, tooling, and components for testing and production optimization.

Aerospace: Manufacturing lightweight, complex aircraft components, reducing weight and improving fuel efficiency.

Consumer Goods: Customizing products such as jewelry, fashion accessories, and home décor items with intricate designs and textures.

Impact on Manufacturing and Innovation

Speed and Efficiency: Accelerating product development cycles and reducing time-to-market through rapid prototyping and on-demand production.

Design Freedom: Empowering designers to explore creative designs and geometries that were previously impossible or costly to produce.

Sustainability: Minimizing material waste and energy consumption compared to traditional manufacturing methods.

Localized Production: Facilitating decentralized manufacturing and reducing reliance on global supply chains.

Challenges and Considerations

Material Limitations: Overcoming challenges related to material properties, durability, and performance in specific applications.

Quality Assurance: Ensuring consistent quality and reliability of printed parts through rigorous testing and validation processes.

Regulatory Compliance: Addressing regulatory requirements and standards for safety, quality, and environmental impact.

Future Outlook

As 3D printing technology continues to evolve with advancements in materials science, printing processes, and software capabilities, its adoption across industries is expected to grow. With ongoing innovation and integration into manufacturing workflows, 3D printing is poised to drive new levels of customization, efficiency, and sustainability in the global economy.

More Articles

Public Key Infrastructure (PKI) in Blockchain: Ensuring Secure Transactions

3 min read | 25 Jul 2024

Tokenization: Digitizing Real-World Assets on the Blockchain

2 min read | 24 Jul 2024

Permissioned vs. Permissionless Blockchains: Which is Better?

5 min read | 23 Jul 2024

Nodes in Blockchain: The Building Blocks of Decentralization

3 min read | 22 Jul 2024

More Articles

The Art of Storytelling: Immersive Narratives in Augmented Reality

6 min read | 05 Sep 2024

Holo-Homes: How AR and VR are Redefining Interior Design

4 min read | 04 Sep 2024

Beyond the Screen: Exploring AR and VR in Everyday Life

7 min read | 03 Sep 2024

AR for Education: Making Learning Interactive and Fun

5 min read | 11 Sep 2024